Innovating for a Greener Future

America’s cement producers are building a better future with innovative, sustainable practices that reduce environmental impact. The EPA has recognized the industry for driving significant improvements in energy efficiency.

Reduction in carbon footprint by switching to portland-limestone cement.

Cement produced by PCA members is lower-carbon portland-limestone cement.

US CO2 emissions represented by cement manufacturing process today.

The Concrete Life Cycle

Concrete is resilient. When you look at the lifetime of the built environment, the energy savings and emissions reductions achieved by building with concrete more than offset the emissions from cement manufacturing.

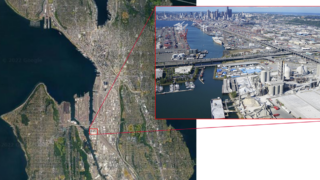

If the entire U.S. road system used concrete pavement, we could reduce GHG emissions per year by 46.5 million metric tons.

Paving the Way to Net Zero

Concrete is one of the most sustainable construction materials—but industry is working to make it even better. The PCA Roadmap to Carbon Neutrality is an ambitious plan for the future.

Carbon Neutrality

Cement manufacturers are making big changes to reach carbon neutrality by 2050. The industry is working with policymakers, advancing sustainable technologies, and developing greener types of cement.

Sustainable Construction Codes

Sustainable construction codes and green rating systems inform better decisions for longer-term, sustainable projects. They also provide benchmarks for recognizing sustainable achievements.

Keep Learning

Dig into the PCA Reference Library’s online resources to learn more about sustainability in the cement industry.

Get in Touch

Lindsey Geiger, PE, LEED AP BD+C, ENV SP

Director, Environment and Sustainability

James A. Farny, FACI

Director, Environmental Measurement and Metrics