2024 Safety Innovation Award Winners

Grinding Media Hopper

Ash Grove Cement, a CRH Company

Seattle Cement Plant – Seattle, WA

The team at Ash Grove Cement’s Seattle Plant designed a special hopper for grinding media used in the ball mill. Reducing hand and soft tissue injuries, the new hopper device is approximately 6 feet by 6 feet standing on 4 legs, one at each corner. The innovation has a spike in the center that splits baffle bags, causing grinding balls to drop through an opening in the hopper and onto a bucket elevator into the ball mill. The device enhances safety by removing manual handling of the baffle bags.

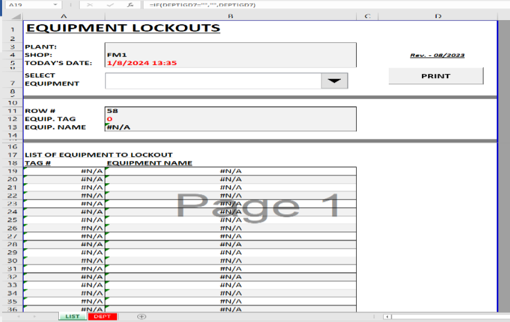

Complex Lock – Tag – Try Matrix System

GCC

Tijeras Cement Plant – Tijeras, NM

Complex lock – tag – and try safety procedures in maintenance work carry risk to everyone working on the equipment. Combining contractor and plant employees together to do one job can multiply the challenges. Recognizing the need for a better system, the team at Tijeras Plant developed software that allows a user to select one piece of equipment from a menu, which then lists all the other equipment that needs locked out before everyone can work safely.

Connected Gate System

Heidelberg Materials

Union Bridge Plant – Union Bridge, MD

Searching for a new methods and procedure to prevent falls, the group at Heidelberg Materials Union Bridge Plant engineered a connected gate system on the burner deck that allows miners to move materials and supplies onto the platform without using safety harnesses tied off to an anchor. The new system involves an employee standing in a safe position to raise a gate that opens a side as another gate on the opposite side automatically lowers itself. There is never a time when there’s an opening, so never a chance of anyone falling.

Gearbox Platform

Salt River Materials Group

Clarkdale Plant – Clarkdale, AZ

The most dangerous jobs in heavy manufacturing are those done infrequently or irregularly. Knowing the 47 ton 11 feet tall vertical mill gearbox had to be replaced, the miners at Salt River Materials Group Clarkdale Plant brainstormed with contactors to build a platform that employees raises and lowers as the work progresses. Employees can now roll the platform next to the gearbox and raise or lower it using pins to hold it in place as needed. A great advantage with the new system is that employees no longer use cranes or cribbing on the job.