Uses in Infrastructure

Water Resources

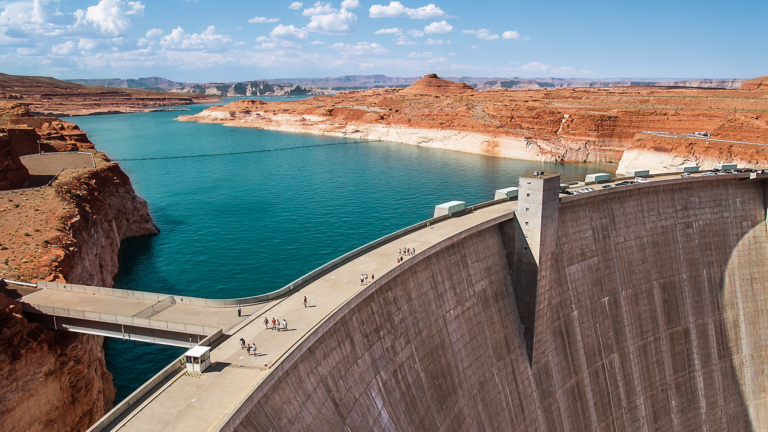

Establishing consistent and resilient water supplies has been essential to the ability of society to exist and thrive for centuries. As the global population continues to grow, our need to conserve and recycle fresh water is growing even more urgent.

Cement and concrete have long played a vital role in all aspects of water resources infrastructure. Once used in the construction of man-made pools, aqueducts, and similar structures, today, it’s found in dams, reservoirs, shorelines, canals, and more. Years of research, development, and testing have led to new technologies that significantly improve the function and efficiency of these systems.

Applications of Cement such as roller-compacted concrete, soil-cement, slurry cuttoff walls, and cementitious grouting are widely used in water resource projects throughout the United States and around the world. These materials have helped build new long-lasting structures, rehabilitated existing structure to extend their useful life, and contributed to an overall improved quality of life for our society.

Roller Compacted Concrete Applications

Roller-Compacted Concrete (RCC) is a ”zero-slump” concrete containing cement, aggregate, and water, typically placed using dozers and compacted with vibratory steel drum rollers. The speed of construction and long-term performance make RCC ideal for many water resource applications.

-

Dams have played a pivotal role in securing and managing water resources to improve quality of life for thousands of years. They serve multiple purposes, including flood control, irrigation, drinking water supply, and hydroelectric power generation.

An Aging Infrastructure

The United States currently has more than 91,000 dams in service, regulated through various dam safety programs by organizations such as the Corps of Engineers, Bureau of Reclamation, and Natural Resources Conservation Service. Many of these dams are more than 50 years old and need rehabilitation.

Climate Change

Climate change predictions suggest longer drought periods and larger flood events may be on the horizon, making a strong case for building new dams and repairing or upgrading existing ones to accommodate harsher conditions.

The Benefits of RCC

Roller-compacted concrete is a common method for building new dams and rehabilitating existing ones. RCC can be applied like armor plating to protect earthen dams from washing out or failing due to wave erosion or when overtopped by floodwaters.

Resources

Webinars to Watch

PDFs to Download

- Design Manual for RCC Spillways and Overtopping Protection

- Design Manual for Small RCC Dams

- Guide for Developing RCC Specifications and Commentary

- Roller-Compacted Concrete Quality Control Manual

- Roller Compacted Concrete (RCC)

- Facing Systems for Roller-Compacted Concrete Dams and Spillways

- Roller-Compacted Concrete Density: Principles and Practices

- Bonding Roller-Compacted Concrete Layers

- Dam Construction and Facing with Soil-Cement

- Erosion Abrasion Resistance of Soil-Cement and Roller-Compacted Concrete

- Buttressing an Aging Gravity Dam with RCC to Remedy Flood Risk

- New RCC Dam Replaces 70-Year Old Concrete Dam

- RCC Dam Saves City’s Sole Source of Water Supply

- Design/Build Approach Big Success for Pine Brook RCC Dam

- Hickory Log Creek RCC Dam and Reservoir Will Supply Much Needed Water

- Elkwater Fork Dam – A Reliable Source of Drinking Water

-

Spillways are an essential components of every dam. They act as a release valve for dams, providing controlled release of water into the downstream area — typically the riverbed below —to protect dams from overtopping. Proper design and the use of materials like RCC ensure the durability and effectiveness of spillways, safeguarding both the dam and the surrounding communities and environment.

Types of Spillways

- Principal Spillways: Principal spillways are used to pass normal inflows and are also commonly referred to as service spillways. Conventional vibrated concrete is commonly used to construct principal spillways to stand up to more frequent flood events.

- Auxiliary Spillways: When a dam structure requires a spillway capacity in excess of the service capacity of the principal spillway, an auxiliary spillway is constructed to convey the additional flow. RCC overtopping protection spillways have been used extensively to retrofit earthen embankment dams with essential auxiliary spillway capacity to allow safe conveyance of infrequent flood events.

Some Design Considerations for Spillways

- Spillway location: The location of the spillway is one of the most important decisions of spillway design because the location has implications for dam safety and public safety, as well as hydraulics and energy dissipation, aesthetics, cost, and maintenance.

- Adequate spillway capacity: The spillway’s opening and control section must be designed to discharge floodwaters without allowing upstream water levels to rise too high. This ensures that the dam does not harm the surrounding landscape or disturb nearby residents and prevents uncontrolled overtopping of the dam which could lead to a breach and release of the impoundment.

- Energy dissipation: Spillways need to be large enough or include features to dissipate the energy of the water flowing from the dam to avoid damaging the dam’s structure and foundation.

- Avoiding Human Error: Discharge of surplus water that occurs without requiring manual activation of a control feature such as a gate can improve safety during a flood event.

The Benefits of RCC

Conventional concrete and roller-compacted concrete are the materials of choice to build spillway and conveyance structures to safely and reliably move water from the upstream to downstream area of dams.

- RCC can be applied quickly to create durable structures resistant to erosion and damage during extreme flood events.

- Concrete mats and grout-filled mats can also prevent erosion during runoff periods and maintain the stability of embankment slopes, channel linings and streambanks.

Other Hydraulic Structures

RCC can provide erosion protection in existing vegetative earthen auxiliary spillways, provide support as the foundation for conventional vibrated concrete spillways, and be used to construct drop structures to protect a channels slopes and invert.

Resources

Webinars to Watch

PDFs to Download

- Design Manual for RCC Spillways and Overtopping Protection

- Guide for Developing RCC Specifications and Commentary

- Roller-Compacted Concrete Quality Control Manual

- Erosion Abrasion Resistance of Soil-Cement and Roller-Compacted Concrete

- Roller-Compacted Concrete Density: Principles and Practices

- Project Profile McKinney Lake Dam

- Arc-Shaped RCC Spillway Triumphs in Dam Rehab

- Aesthetics Play Key Role in Dam Rehabilitation

Soil Cement Applications

For over 80 years, soil-cement (SC) has been used worldwide to help protect water resources infrastructure by preventing erosion and water leakage.

-

Wave action makes water a destructive force to unprotected earthen embankments. Protecting these embankments with various concrete and soil-cement materials protect against erosion, minimize maintenance and extend the lifespan of the structure.

Cement can be used to protect banks in various ways. These include not only soil-cement, but also roller-compacted concrete, articulating concrete block (ACB) mats, grout-filled mats, and even large pieces of recycled concrete aggregate!

Benefits of SC

Soil-cement has been used extensively throughout the United States for upstream slope protection, streambank stabilization, and grade control structures.

- Soil-cement is strong, durable, and economical for erosion control.

- It serves as a low-permeability liner for reservoirs and waste containment ponds.

- Using on-site or locally available soils, soil-cement provides an sustainable solution for various water resource applications.

Resources

PDFs to Download

- Soil-Cement Guide for Water Resources Applications

- Erosion Abrasion Resistance of Soil-Cement and Roller-Compacted Concrete

- Dam Construction and Facing with Soil-Cement

- Upstream Slope Protection Repair

- Soil-Cement Plays Key Role in Protecting Large Water Impoundments at Nuclear Generation Station

- Rueter-Hess Dam and Reservoir to Solve Water Shortage Problems

- Soil-Cement for Erosion Protection of Flood-Control Levee in Phoenix, AZ

- Soil-Cement for Water Control, Laboratory Tests

-

The advantages of using soil-cement as a lining for open flumes were first demonstrated in 1943 by research conducted at the Hydraulics Laboratory at Oklahoma State University in Stillwater, OK.

Over the 80 years since, soil-cement has been successfully implemented to protect miles of channels—most commonly for flumes conveying water for irrigation, domestic supply, flood routing, and cooling water to and from power plants.

Benefits of SC

- Minimizes water loss due to seepage through the channel walls and bottom.

- Helps resist erosion and abrasion from flowing water.

Resources

PDFs to Download

- Soil-Cement Guide for Water Resources Applications

- Erosion Abrasion Resistance of Soil-Cement and Roller-Compacted Concrete

- Dam Construction and Facing with Soil-Cement

- Upstream Slope Protection Repair

- Soil-Cement Plays Key Role in Protecting Large Water Impoundments at Nuclear Generation Station

- Rueter-Hess Dam and Reservoir to Solve Water Shortage Problems

- Soil-Cement for Erosion Protection of Flood-Control Levee in Phoenix, AZ

- Soil-Cement for Water Control, Laboratory Tests

-

Reservoirs, canals, and other water-retaining structures need reliable protection from leakage. Liners have become a crucial measure to improve the performance of these structures.

Traditionally, clay and other materials were used to line reservoirs due to their ability to resist leakage once a certain water threshold was reached. After World War II, scientists found that soil-cement had a much lower average seepage loss than some clay reservoirs. This discovery led to further testing and the adoption of soil-cement as a liner material.

Benefits of SC

- Low Seepage Loss: Soil-cement has lower average seepage loss compared to traditional clay liners.

- Durability: Provides long-term protection and stability.

- Economy: Using locally available soils makes it a cost-effective solution.

- Versatility: Applicable in a variety of water resource projects, from small ponds to large reservoirs.

Applications of Liners

Liners are now used in a variety of applications, including:

- Ponds

- Reservoirs

- Landfills

- Canals

- Facings for dams

- Protective barriers beneath streets and buildings

Resources

PDFs to Download

- Soil-Cement Plays Key Role in Protecting Large Water Impoundments

- Ash Settling Pond

- Equalization Ponds

- Sludge-Drying Lagoons

- Soil-Cement for Facing Slopes, and Lining Reservoirs, Channels, and Lagoons

- Soil-Cement for Water Control, Laboratory Tests

- Suggested Specification for Soil-Cement Linings for Lakes, Reservoirs, Lagoons

-

Soil-cement offers an effective approach to preventing stream channels from degrading by reducing the velocity of flowing water. This is achieved by creating small soil-cement grade control structures. The structures decrease the water velocity in the upstream reach, reducing the potential for erosion. The water spills over the grade control structure and re-enters the natural channel at a lower speed.

Grade control structures are particularly effective at protecting bridge abutments and piers from erosion when constructed immediately downstream from these structures. They help maintain the integrity of the stream channel and nearby infrastructure by controlling water flow and reducing erosion risks.

Material Considerations

In areas where bedload sediment transport is frequent and consists of larger sediment sizes (such as gravels, cobbles, and boulders), more erosion-resistant materials are necessary. In these cases, conventional concrete or roller-compacted concrete (RCC) are preferable to soil-cement.

-

Geotechnical applications of cement are commonly used for dam and levee rehabilitation projects to address a wide variety of deficiencies.

- Slurry cutoff walls and the deep mixing method (DMM) are effective solutions that have been used to remediate excessive seepage through dam and levee embankments and their foundations. (See Slurry Cutoff Walls and DMM below)

- Cementitious grouting is another commonly used method to address seepage in earthen embankment and concrete hydraulic structures and dams. (See grouting below.)

- Grouting is also effective at modifying the physical properties of dams and their foundations to improve performance during seismic events.

Pavements

Portland cement can be used in many pavement layers other than the surface wearing course. In fact, pavement systems containing a variety of cement-bound layers have been used very successfully worldwide for over a century.

Portland cement can be used in many pavement layers other than the surface wearing course. In fact, pavement systems containing a variety of cement-bound layers have been used very successfully worldwide for over a century.

Watch the webinar “Integrated Pavement Solutions with PC”

Common Applications

- Integrating multiple cement-based layers into a pavement design may provide a cost-effective method for achieving a stronger, more durable, sustainable pavement.

- Use of cement can improve the quality of subgrade soils and stabilizing base materials.

- Cement is used in numerous pavement repair techniques.

- It contributes to many pavement recycling and reclamation applications.

Choice of Materials

With so many applications, deciding which cement-based materials are best to employ depends on the specific pavement project. See some options below.

Concrete Applications

Concrete is a durable, economical and sustainable solution for state highways, rural roadways, residential and city streets, intersections, airstrips, intermodal facilities, military bases, parking lots, and more.

-

Concrete Pavement can be used for pavement reconstruction, resurfacing, restoration, or rehabilitation, as well as for building new pavements.

Benefits of Concrete Pavement

- Long life: Concrete pavements have an average service life of 30 to 50 years.

- Low maintenance requirements and costs: No need for repeated resurfacing, frequent spot repairs, or patching.

- Smoother traffic flow: Concrete pavement construction doesn’t require lengthy lane closures. Roads can be reopened in as little as six hours.

- Low life-cycle cost: Consumes minimal materials, energy, and other resources for construction, maintenance, and rehabilitation throughout its service life.

- Safety: Concrete pavement is less susceptible to forming heavy-vehicle wheel ruts. It’s also easier to see at night, ensures shorter vehicle stopping distances in wet weather. And, due to its longevity, requires fewer work zones over its lifespan.

Resources

PDFs to Download

-

Roller-compacted concrete (RCC) is named for the construction method used to build it. RCC is a “zero slump” mixture that is stiff enough to be compacted by vibratory rollers after being placed with conventional earthmoving or paving equipment.

RCC is used in both mass concrete applications, such as constructing dams, and in relatively thin flat layers, such as pavements.

Resources

Webinars to Watch

- Roller-Compacted Concrete for Pavements

- Applications of Roller-Compacted Concrete for Dams

- Design and Testing of Roller-Compacted Concrete

- RCC for Pavements

PDFs to Download

- Subgrades and Subbases for Concrete Pavements

- Guide Specification for Construction of Roller Compacted Concrete Pavements

- Roller Compacted Concrete Pavements for Highways and Streets

- Production of Roller Compacted Concrete

- Frost Durability of Roller Compacted Concrete Pavements: Research Synopsis

- Thickness Design of a Roller Compacted Concrete Composite Pavement System

- Roller Compacted Concrete Pavements – A Study of Long Term Performance

- Effect of Density on Mechanical Properties and Durability of Roller Compacted Concrete

- Roller Compacted Concrete (RCC)

- Guide to Cement-Based Integrated Pavement Solutions

-

Minimizing environmental impacts is crucial for sustainable development. Traditionally, impervious pavement surfaces increased stormwater runoff and required larger conveyance and treatment systems.

To address this, designers now incorporate pervious concrete into stormwater management systems. Pervious concrete reduces runoff volume, enhancing both environmental and economic sustainability. In fact, use of pervious concrete is among the Best Management Practices recommended by the EPA and other agencies for stormwater runoff management.

Read More About Pervious Concrete

Resources

PDFs to Download

Soil-Cement Applications

Different types of soil-cement (SC) mixtures are used in pavement construction and rehabilitation to make the ground stronger and to reduce volume changes and plasticity. Soil-cements are especially helpful in areas with fine-grained soils and highway embankments.

-

Full Depth Reclamation with cement uses the materials from deteriorated asphalt pavement, and, with the addition of cement, creates a new stabilized base. The recycled base is stronger, more uniform, and more moisture resistant than the original base, resulting in a long-lasting, low-maintenance life. Recycling costs are typically 40 to 80% less than removing and replacing old pavement—and of course, this is a more sustainable solution.

Resources

Webinars to Watch

PDFs to Download

- Guide to Full-Depth Reclamation with Cement

- Guide to Cement-Based Integrated Pavement Solutions

- Soil-Cement Laboratory Handbook

- Reflective Cracking in Cement Stabilized Pavements

- Long-Term Performance of Full-Depth Reclamation with Portland Cement: Research Synopsis

- Performance of Soil-Cement and Cement-Modified Soil for Pavements: Research Synopsis

- Microcracking

- Soil-Cement Inspector’s Manual

- Soil-Cement for Commercial Sites

- Evaluating the Performance of Soil-Cement and Cement-Modified Soil for Pavements: A Laboratory Investigation

- Minimizing Cracking in Cement-Treated Materials for Improved Performance

- Thickness Design Systems for Pavements Containing Soil-Cement Bases

- Evaluation of Laboratory Durability Tests for Stabilized Aggregate Base Materials

- Effects of Environmental Factors on Construction of Soil-Cement Pavement Layers

- Slurry Stabilization and Reaction Chemistry Of Cement-Treated Soils

- Full-Depth Reclamation using Portland Cement: A Study of Long-Term Performance

- Full-Depth Reclamation: Recycling Roads Saves Money and Natural Resources

Case Histories

-

Cement-Modified Soil (CMS) and Cement-Stabilized Subgrade (CSS) are two types of soil-cement applications. Both CMS and CSS enhance the physical properties of native soils, extending the life of pavements or structures by offering uniform support through a durable, stable, and typically non-expansive foundation.

CMS uses a small amount of portland or blended cement to treat soils, creating a stable working platform. This process reduces the plasticity and shrink/swell potential of unstable, wet, or expansive soils while increasing their bearing capacity. CSS provides all the benefits of CMS. It also substantially increases soil stiffness and strength, providing measurable structural advantages.

Resources

Webinars to Watch

PDFs to Download

- Guide to Cement-Stabilized Subgrade Soils

- PCA Soil Primer

- Guide to Cement-Based Integrated Pavement Solutions

- Soil-Cement Laboratory Handbook

- Properties and Uses of Cement-Modified Soil

- Soil-Cement for Commercial Sites

- Evaluating the Performance of Soil-Cement and Cement-Modified Soil for Pavements: A Laboratory Investigation

- Comparative Performance of Portland Cement and Lime Stabilization of Moderate to High Plasticity Clay Soils

- Effectiveness of Portland Cement and Lime in Stabilizing Clay Soils

- Performance of Cement-Modified Soils: A Follow-Up Report

- Stabilization of Clay Soils by Portland Cement or Lime – A Critical Review of Literature

- Evaluation of Laboratory Durability Tests for Stabilized Subgrade Soils

- Slurry Stabilization and Reaction Chemistry Of Cement-Treated Soils

Case Histories

-

Cement-Treated Base (CTB) is a type of soil-cement that involves mixing native soils or manufactured aggregates with precise amounts of portland or blended cement and water. After compaction and curing, this mixture hardens to form a strong, durable, and frost-resistant paving material. It’s used in projects involving highways, roads, and streets; parking areas; airports; and materials handling and storage areas.

CTB has various benefits:

- Creates a strong, durable, and frost-resistant paving material.

- Can be mixed in place and compacted after blending or mixed in a central plant and then hauled to the placement area.

Resources

Webinars to Watch

PDFs to Download

- Soil-Cement Laboratory Handbook

- Guide to Cement-Treated Base (CTB)

- Guide to Cement-Based Integrated Pavement Solutions

- Reflective Cracking in Cement Stabilized Pavements

- Performance of Soil-Cement and Cement-Modified Soil for Pavements: Research Synopsis

- Microcracking

- Soil-Cement Inspector’s Manual

- Soil-Cement for Commercial Sites

- Evaluating the Performance of Soil-Cement and Cement-Modified Soil for Pavements: A Laboratory Investigation

- Minimizing Cracking in Cement-Treated Materials for Improved Performance

- Soil Stabilization Field Trial

- Thickness Design Systems for Pavements Containing Soil-Cement Bases

- Evaluation of Laboratory Durability Tests for Stabilized Aggregate Base Materials

- Effects of Environmental Factors on Construction of Soil-Cement Pavement Layers

- Slurry Stabilization and Reaction Chemistry Of Cement-Treated Soils

Case Histories

Geotechnical

Nearly every modern structure is built on a foundation made of cement and concrete. Cement and concrete solutions are durable against harsh underground conditions, economical, resilient, and versatile, making them ideal for various geotechnical applications. For example, lightweight cellular concrete is used to compensate for heavy structures where ground conditions have a low bearing capacity, and also to backfill pipes to permanently abandon them in place. Slurry cutoff walls rely on the low permeability of a mixture of soil, portland or blended cement and often bentonite to create long-lasting barriers that prevent the flow of water and/or contaminants.

Nearly every modern structure is built on a foundation made of cement and concrete. Cement and concrete solutions are durable against harsh underground conditions, economical, resilient, and versatile, making them ideal for various geotechnical applications. For example, lightweight cellular concrete is used to compensate for heavy structures where ground conditions have a low bearing capacity, and also to backfill pipes to permanently abandon them in place. Slurry cutoff walls rely on the low permeability of a mixture of soil, portland or blended cement and often bentonite to create long-lasting barriers that prevent the flow of water and/or contaminants.

Soil-Cement Applications

Soil-Cement (SC) is an engineered, densely compacted mixture of soil or aggregate, portland or blended cement, other possible cementitious materials, and water.

In geotechnical environments, SC is used in:

- Modification or stabilization of foundation soils

- Slurry cutoff walls

- Deep mixing methods

Benefits of Soil-Cement

- On-site soils are amended to achieve desired physical properties.

- SC builds long-lasting structures that are economical.

- These structures have a low environmental impact over their lifespan.

-

Waste Solidification/Stabilization (S/S) is a common method for managing and disposing of contaminated wastes, especially those classified as hazardous in the United States. This treatment involves mixing a binding reagent, such as portland or blended cement, into the contaminated waste. Cement is used alone or with additives and will continue to be integral in the sustainable development and management of contaminated wastes.

Treatment Process

Treatment immobilizes the contaminants within the treated material in one of three ways:

- Solidification: The waste is bound in a matrix of cemented material.

- Stabilization: The waste is chemically altered into an insoluble form.

- Combination: Both solidification and stabilization may be used. Immobilization prevents contaminants from migrating to human, animal, and plant receptors.

Benefits of SC

- Availability and Versatility: cement is widely available and adaptable for various applications.

- Effective Treatment: Provides solidification, stabilization, and some liquid sorption.

- Long-Term Performance: Over 70 years of successful use in S/S systems.

Resources

PDFs to Download

- Solidification and Stabilization of Wastes Using Portland Cement

- Guide to Improving the Effectiveness of Cement-Based Stabilization/Solidification

- Solidification/Stabilization of Contaminated Soil

- Cement-Based Solidification/Stabilization of Lead-Contaminated Soil at a Utah Highway Construction Site

- Solidification/Stabilization for Remediation of Wood Preserving Sites: Treatment for Dioxins, PCP, Creosote, and Metals

Case Studies

- Remediation of Lead- and Petroleum-Contaminated Soils at a Boston Brownfield Site Using Cement-Based Solidification/Stabilization

- Solidification/Stabilization Treatment at a Former Manufactured Gas Plant Site

- Solidification/Stabilization Treatment of Arsenic- and Creosote-Impacted Soil at a Former Wood-Treating Site

- Augusta Manufactured Gas Plant Cleanup Using Cement-based Solidification/Stabilization

- New Bedford Harbor Superfund Site Area D Bulkhead Project

- Solidification/Stabilization Treatment of Dredged Material from the Port of San Diego

- In-Situ Solidification/Stabilization of a Former Wood Treatment Site

- S/S Treatment of Dioxin Soils at Naval Construction Battalion Center Gulfport

- Phoenix-Award Winning Kendall Square Rises from Cement-Treated Brownfield Site

- CQA Methodologies for In-Situ S/S at Former Manufactured Gas Plants

- Solidification/Stabilization Treatment at the Brunswick Wood Preserving Superfund Site

- Remediation of Hercules 009 Landfill

Other Resources

-

Deep Mixing Method (DMM), also known as deep soil mixing or cement deep soil mixing (DSM/CDSM), is an in-situ soil treatment technique. It involves blending native soils or fills with cementitious and/or other materials (binders). This treatment enhances the strength and reduces the compressibility of the treated ground compared to untreated soil.

Types of DMM

- Wet mixing involves injecting binders in slurry (wet) form to blend with the soil. Techniques include single-auger, multi-auger, or cutter-based mixing. This creates isolated elements, continuous walls, or blocks.

- Dry mixing uses binders in powder (dry) form. They react with the moisture already present in the soil.

DMM Applications

- Large-scale foundation improvement

- Earth retaining systems

- Hydraulic barriers

- Contaminant/fixation systems

Benefits of DMM

- Utilizes In-Situ Soils: Cement is used to ammend in-situ soils minimizing truck traffic and off-site disposal.

- Availability: Cement is widely available and easy for contractors to acquire.

Other Applications

See how various types of cement and cementitious materials can be used in the following applications.

-

Lightweight Cellular Concrete (LCC) is a mixture of portland or blended cement, water, and air created using a preformed foaming agent. LCC serves as a lightweight, strong, durable, and cost-effective soilfill replacement for various geotechnical applications.

LCC Applications in Geotechnical Environments

- Lightweight road bases and fills

- Bridge approach embankments

- Void and cavity filling

- Pipe and culvert abandonment filling

- Annular space tunnel grout filling

- Foundation fills

- Energy arresting systems

- Retaining wall backfills

- Lightweight dam and levee structural fills

- Landslide repair and slope stabilization

- Controlled density fill

Benefits of LCC

- LCC is lighter in weight than soil.

- It’s highly flowable, able to fill spaces of any size and shape.

- It is cost-effective compared to many alternatives.

- The material can be produced and placed on-site, reducing material transportation volume.

- Requires relatively small equipment and labor support to help minimize the congestion on a job site.

Resources

Webinars to Watch

PDFs to Download

-

Slurry Cutoff Walls are nonstructural underground barriers designed to prevent the horizontal flow of water and other fluids. They are commonly used for surrounding tunnels, open cuts, and foundations. The walls are constructed using a viscous stabilizing fluid known as slurry.

Cement-Bentonite Method

In the cement-bentonite (C-B) method, cement is added to the bentonite water slurry just before it is introduced into the trench. The slurry stabilizes the trench during excavation and then sets to form a permanent cutoff wall.

Benefits of the C-B Method

- Slurry maintains trench excavation stability throughout construction of the cutoff wall.

- The chemical properties of the cement and bentonite can improve permeability reduction performance.

Resources

PDFs to Download

-

Cementitious Grouting is a process where fluid cementitious grout is pumped under pressure to fill forms, voids, and cracks. It is used in various settings, including bridges, marine structures, dams, and rock anchors. The grout enhances the strength and stiffness of the treated mass and reduces its permeability.

Benefits of Cementitious Grouting

- Cost-Effective: Cement grouting is often more economical for underpinning structures than alternatives like removing, replacing, or piling.

- Accessibility: It can be performed in difficult-to-access areas and limited spaces.

- Adaptability: It’s effective regardless of structural connections, making it suitable for existing foundations without disrupting normal facility operations.

Resources

PDFs to Download